Sicoma PA102 Seal (U-Cup Shaft Seal) 170×180×13 mm – MAO 3000/2000

Function of Sicoma PA102 U-Cup Seal 170×180×13 mm (MAO 3000/2000)

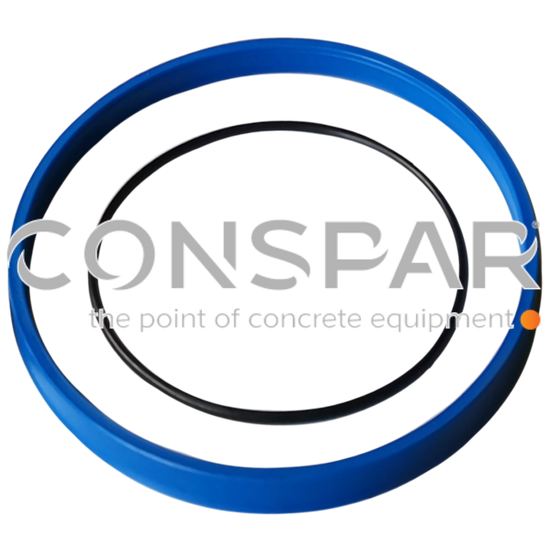

The Sicoma PA102 is a dynamic U-cup shaft seal (170×180×13 mm) used in specific shaft-end sealing configurations on SICOMA MAO 3000/2000 twin-shaft concrete mixers. Its job is to help keep grease where it should be and reduce slurry/dust ingress toward the bearing zone during heavy-duty mixing.

You may also find this part referenced in catalog wording as “PA102 U-cup seal” or “paraolio U-cup 170×180×13 (PA102)”. This page focuses on the PA102 profile + dimensions, because on MAO sealing groups, shape and size matter as much as the code.

Also searched as: PA102 seal, Sicoma PA102 seal, PA102 U-cup seal, paraolio U-cup 170×180×13

Price on request.

✅ Code: PA 102

✅ Size:170×180×13 mm

✅ Fits: MAO 3000/2000

💬📞 WhatsApp: Fast quote. Fitment checked.

✉️ Email: Send your list. We’ll do the matching.

📝 RFQ Form: Drop the basics. Get the offer.

🟠🚚 Dispatch , Typical: Typical dispatch 3–7 business days if in stock; made-to-order items 4–6 weeks after confirmation/payment

Fitment of PA102 Seal to Shaft Sealing Group

PA102 is designed for heavy-duty shaft sealing groups used on larger SICOMA MAO series twin shaft mixers, commonly operating in high-capacity ready-mix concrete batching plants and precast concrete production lines.

Important: MAO shaft sealing stacks vary by revision, so fitment must be confirmed against your BOM / exploded view / serial revision before ordering. The same “size-looking” seal can be wrong if the stack profile differs.

Quick pre-checks that prevent wrong orders:

-

Confirm the PA102 code from your parts list or removed seal packaging

-

Confirm the 170 mm shaft and 180 mm seat on your assembly (revision check)

-

Confirm the seal type is U-cup, not a TC oil seal (profile matters)

Dimensions & Specs: 170×180×13 mm (PA102 Seal)

This Sicoma PA102 Seal 170×180×13 mm is sized for:

-

ID (Inner Diameter): 170 mm (shaft side)

-

OD (Outer Diameter): 180 mm (housing seat / groove side)

-

Width: 13 mm

Material & Design Notes:

Sicoma PA102 is built for dynamic sealing in abrasive concrete environments:

-

Body: high-performance Polyurethane (PU) for wear resistance

-

Energizer core: NBR O-ring to maintain consistent sealing force

-

Profile: asymmetric U-cup designed to keep a stable sealing lip under real mixing duty

-

Product type: dynamic shaft U-cup seal (not an oil seal)

Abbreviations:

-

PU: Polyurethane

-

NBR: Nitrile Rubber

-

ID / OD: Inner Diameter / Outer Diameter

Position of PA102 in the Sicoma Sealing Group:

In many MAO shaft-end assemblies, PA102 functions as a primary dynamic barrier within a multi-element sealing stack, working alongside adjacent rings and seals to protect the bearing area. The exact sequence depends on your mixer revision, so confirm the PA102 position using your exploded view before ordering. If you can share a photo of the removed seal and the stack area, we can confirm the correct sealing version faster.

Why Replacement Matters?

A U-cup seal protects only while it maintains reliable lip contact. When the PU sealing edge wears or the energizer ring loses elasticity:

-

sealing force drops under load

-

grease retention weakens

-

dust/slurry contamination begins

-

bearing temperatures rise and wear accelerates

The practical result is often unplanned downtime and avoidable damage around the bearing zone and shaft surface.

Compatibility Cross-Reference (Sicoma Seal):

PA102 is commonly confused with oil seals or similarly named codes. Use code + profile + dimensions, not “looks similar.”

-

PA102 — U-cup seal — U-cup profile + energizer core + 170×180×13 — ✅ Reference (PA102 Seal)

-

PA051 — Oil seal (TC) / revision-dependent seal — different seal type/profile — ❌ Not interchangeable

-

PA084 — Oil seal (TC) — oil seal profile, different fitment — ❌ Not interchangeable

-

0228G0001B2 — Oil seal (thin) — different type and dimensions — ❌ Not interchangeable

Best practice before ordering: share your BOM/photo so the sealing version can be matched correctly

Related Parts & Seal Kit Options:

Depending on your MAO sealing version, PA102 is often ordered together with other Sicoma mixer spare parts from the same shaft-end group, such as:

-

adjacent oil seals or intermediate sealing elements (revision-dependent)

-

sealing covers / rings used in the same stack (revision-dependent)

If you are planning downtime service, ask for a seal kit / shaft end seal kit / maintenance kit matched to your revision. Send a photo or parts list, and we’ll build the correct set.

Installation Notes:

-

Seat preparation: clean, smooth, burr-free groove and edges. Small defects can damage the PU lip during assembly.

-

Insertion: PA102 can be gently formed for insertion into closed grooves; avoid sharp tools that can nick the sealing edge.

-

Orientation: install with the U opening facing the pressure (grease) side. Incorrect orientation reduces performance immediately.

-

Final check: confirm the energizer ring sits evenly and the seal is square in its seat without twisting or distortion.

For high-duty mixers, installation should be carried out by a qualified maintenance technician familiar with MAO shaft sealing groups.

RFQ, Lead Time, Commercial & Legal:

Lead time guidance:

-

If in stock: typical dispatch 3–7 business days

-

Made-to-order: typically 4–6 weeks after confirmation/payment

(Some items may be in transit; confirm current lead time before ordering.)

To get an accurate quote, please provide the quantity, the delivery destination, the mixer model, the revision or serial number if you have it, and the BOM or a photo.

Commercial notes: All quotations and proforma invoices for this item are issued in EURO (EUR). Please request a formal offer for current pricing.

Legal notice (compatibility & trademarks): Sicoma is a registered trademark of its respective owner. This spare part is an OEM-equivalent component supplied by Conspar and is not an original Sicoma-branded product. All references to “Sicoma”, mixer models, and OEM codes are used solely to indicate compatibility and correct fitment within the concrete mixer system.